In the world of industrial processes, efficiency and flexibility are paramount. One solution that has gained popularity in recent years is the modular process skid. These pre-engineered, pre-assembled units offer a range of benefits for various industries, streamlining operations and enhancing overall efficiency.

Process Skid Definition

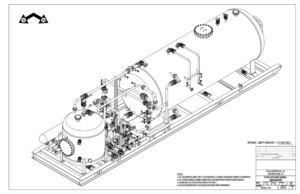

A modular process skid is a compact, self-contained unit that integrates various components of a larger industrial process into a single, transportable module.

These skids are designed and fabricated off-site in a controlled environment and are then transported to the final destination for installation. This approach allows for greater control over the manufacturing process, ensuring quality and consistency.

Key Features

- Compact design: Modular process skids are characterized by their compact and space-efficient design. This minimizes the footprint required for installation, making them ideal for locations with limited space.

- Pre-assembled components: The skids come equipped with pre-assembled components, reducing the need for on-site assembly and minimizing the risk of errors during installation.

- Standardization: The modular nature of these skids allows for the standardization of components and processes, simplifying maintenance and facilitating scalability.

- Ease of integration: Integration with existing systems is often seamless, as modular process skids are designed to easily connect with other equipment and processes in a plant.

Common Applications for Modular Process Skids

Process skids can be used in virtually any application where they streamline processes and better ensure quality. Below are four applications where our team sees them most often.

Chemical Processing

Modular process skids find extensive use in chemical processing plants for tasks such as mixing, heating, and chemical reactions. These skids are tailored to handle specific chemical processes efficiently.

Oil and Gas

Modular process skids play a crucial role in the oil and gas industry, facilitating activities like metering, separation, and dehydration.

Water Treatment

Skids are widely utilized in water treatment facilities for processes such as filtration, disinfection, and chemical dosing.

Pharmaceutical Manufacturing

In the pharmaceutical industry, where precision and cleanliness are crucial, modular process skids are employed for tasks like formulation, blending, and purification.

Top 5 Benefits of Using Modular Process Skids

- Cost-efficiency: Off-site fabrication and standardized components reduce overall project costs, as labor and material expenses are optimized.

- Time savings: The parallel construction of skids while site preparation takes place allows for faster project completion compared to traditional construction methods.

- Quality control: Fabricating skids in a controlled environment enhances quality control, reducing the risk of defects and ensuring consistency across units.

- Flexibility and scalability: Modular process skids offer flexibility in design and can be easily scaled to meet changing production requirements.

- Minimized disruption: Installation on-site is streamlined, minimizing disruption to ongoing operations in the plant.

Process Skids from PALA

At PALA, we deliver high-quality, customized solutions for industrial construction projects. Our fabrication shop employs cutting-edge technologies and a skilled workforce to mechanically design and construct process skids tailored to the unique needs of our clients.

If you need a process skid that meets the highest standards of quality and reliability, we’re here to help. Get started by contacting us online.